Cylinder Boring and Honing Machine

Description

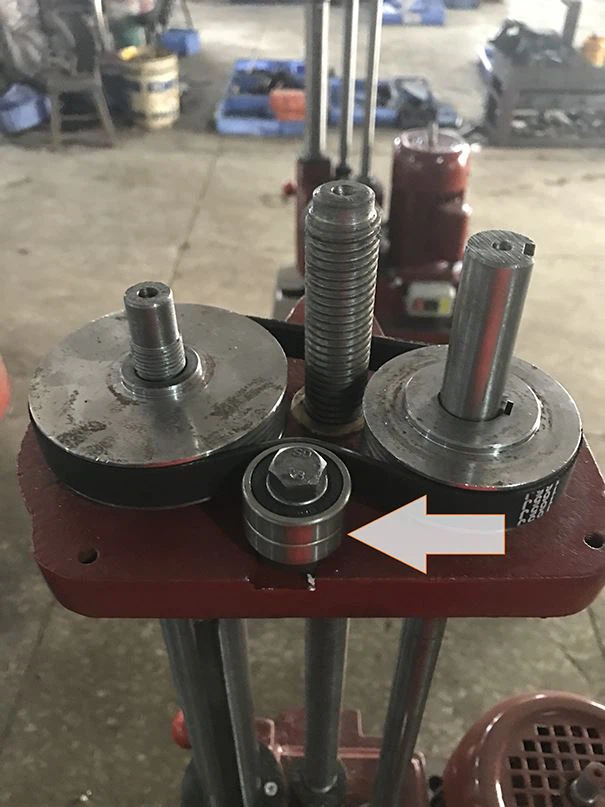

Cylinder Boring and Honing Machine TM807A is mainly used for maintaining the cylinder of motorcycle, etc. After determining the center of the cylinder hole, place the cylinder to be drilled under the base plate or on the plane of the machine base, and fix the cylinder for drilling and honing maintenance. Motorcycle cylinders with a diameter of 39-72mm and a depth of less than 160mm can be drilled and honed. Other cylinders with appropriate requirements can also be drilled and honed if a suitable fixture is installed.

Working Principle and Operating Method

1.Fixing of cylinder body

The mounting and clamping of the cylinder block can be seen in the mounting and clamping assembly. During installation and clamping, a gap of 2-3mm shall be maintained between the packing ring of the upper cylinder and the bottom plate. After the cylinder hole axis is aligned, tighten the upper pressure screw to fix the cylinder.

2. Determination of cylinder hole shaft center

Before boring the cylinder, the rotation axis of the machine tool spindle must coincide with the axis of the cylinder to be repaired to ensure the quality of cylinder repair. The centering operation is completed by the centering device assembly, etc. First, the centering rod corresponding to the diameter of the cylinder hole is connected and installed in the centering device through a tension spring; Put the centering device into the bottom plate hole, turn the hand wheel (disconnect the feed clutch at this time), make the main shaft in the boring bar press the centering ejector rod in the centering device, make the cylinder block hole support firm, complete the centering, tighten the jacking screw in the clamping assembly, and fix the cylinder.

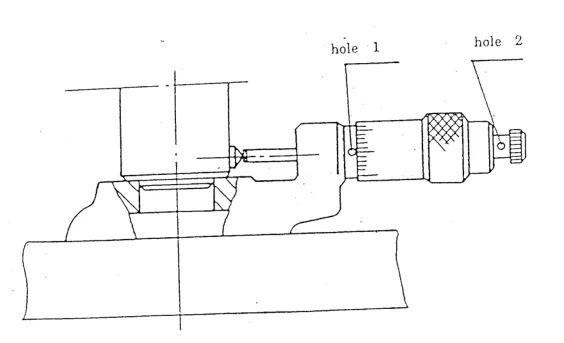

3. Use of specific micrometers

Place a specific micrometer on the base plate surface. Turn the hand wheel to move the boring bar downward, insert the cylindrical pin on the micrometer into the groove under the main shaft, and the contact of the micrometer coincides with the tool tip of the boring cutter. Adjust the micrometer and read out the diameter value of the hole to be bored (the maximum boring amount per time is 0.25mm FBR): loosen the hexagon socket screw on the main shaft and push the boring cutter.

Standard accessories

tool box, accessories box, centering device, centering rod, centering push rod,specific micrometer, press ring of cylinder, press base, packing ring of lower cylinder, boring cutter,

springs for cutter,Hex, socket wrench, multi-wedge belt, spring (for centering push rod), base for honing cylinder, honing tool, clamp pedestal, press piece,adjust support, screw for pressing.

Main Specifications

| odel | TM807A |

| Diameter of boring &honing hole | 39-72mm |

| Max. Boring & honing depth | 160mm |

| Rotational speed of boring &spindle | 480r/min |

| Steps of variable speed of boring honing spindle | 1step |

| Feed of boring spindle | 0.09mm/r |

| Return and rise mode of boring spindle | Hand operated |

| Rotational speed of honing spindle | 300r/min |

| Honing spindle feeding speed | 6.5m/min |

| Electric motor | |

| Power | 0.75.kw |

| Rotational | 1400r/min |

| Voltage | 220V or 380V |

| Frequency | 50HZ |

| Overall dimensions(L*W*H) mm | 680*480*1160 |

| Packing(L*W*H) mm | 820*600*1275 |

| Weight of main machine(approx) | N.W 230kg G.W280kg |

Xi'an AMCO Machine Tools Co., Ltd is a professional company who are specialized in producing, researching and developing and supplying all kinds of Machines and equipments. The products concerned include five series, they are Metal Spinning series, Punch and Press series, Shear and Bending series, Circle rolling series, Other special Forming series.

We had passed ISO9001 quality control certificates. All products are produced according to exporting standard and conform to the inspection standard of exported product of the People republic of China. And some products has passed CE certificate

With our experienced Research and Develop department, we can design and produce the special machine according to customer individual requirements, improve machine quality to satisfy the demand of customer and market.

With Experienced sales team, we can offer you quickly, exactly and completely response.

Our after-sales service can make you rest assured. Within the scope of one-year warranty, we will give you free replacement parts if the fault is not caused by your wrong operation. Outside the warranty period, we will give you good suggestions to solve the problem.