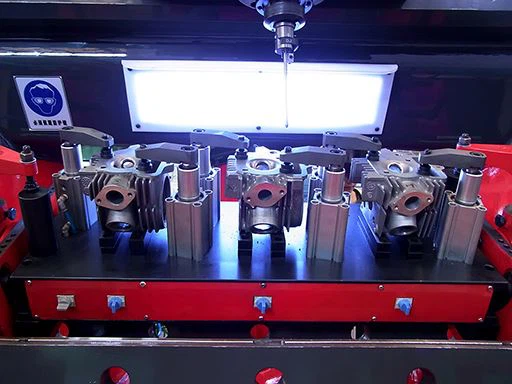

Air Floating Auto-Centering TQZ8560A

Description

Air Floating Auto-Centering TQZ8560A is suitable for repairing the valve seat of automobiles, motorcycle, tractor and other engines. It also can be used to drilling and boring etc. The machine features are air-floating, vacuum clamping, high positing precision, easy operation.The machine is set with grinder for cutter and vacuum check device for workpiece.

Air Floating Auto-Centering TQZ8560A full air float automatic centering valve seat boring machine is used to repair and process engine cylinder head valve seat cone, valve seat ring hole, valve seat guide hole machine tool can also be drilling, expanding, reaming, boring and tapping machine tool with rotary fast clamping fixture, can be used to V Cylinder head processing, equipped with various sizes of centering guide rod and molding tool, to meet the common automobile, tractor and other valve seat maintenance processing.

Machine Features

1.Frequency motor spindle,stepless speed.

2.Regrinding cetter with machine grinder.

3. Widely used,rapid clamping rotary fixture.

4.Supply all kinds angle cutter according order.

5.Air floating,auto-centering,vacuum clamping,high accuracy.

6.Rupply vacuum test device for checking the valve tightness.

TQZ8560 and TQZ8560A are different in shape and size. TQZ8560 is two support columns, and A is three support columns. A looks more beautiful and generous, and the work table is more load-bearing.

Specification

| Model | TQZ8560A |

| Spindle travel | 200mm |

| Spindle speeds | 0-1000rpm |

| Boring rang | F14-F60mm |

| Spindle swing angle | 5° |

| Spindle cross travel | 950mm |

| Spindle longitudinal travel | 35mm |

| Ball seat move | 5mm |

| Angle of clamping device swing | +50°:-45° |

| Spindle motor power | 0.4kw |

| Air supply | 0.6-0.7Mpa;300L/min |

| Max. Size of cylinder cap for repairing (L/W/H) | 1200/500/300mm |

| Machine weight(N/G) | 1100KG/1300KG |

| Overall dimensions(L/W/H) | 1910/1050/1970mm |

TQZ8560A

TQZ8560

The Pneumatic System

air source used in machine tools must, in accordance with the provisions of the interface connection, strictly avoid water, oil, dust and corrosive gas into a pneumatic system and damage the pneumatic components.

the pneumatic system components installed in the spindle box, columns, the audience and each position right after the operation panel, speed control valve in the spindle box.

with five cylinder machine, a sphere in upper part, used for ball clamp, two in the spindle box, used for tee automatically return, the other two installed below the workbench, tighten clamp pad iron.To drag board

pneumatic system, ball, ball seat for automatic clamping, the processed workpiece vacuum sealing detection.

Warm Tips

Matters needing attention

the machine tool should be always kept clean, clean carefully before using the ministries.

the machine should be in the absence of dust, vapor, oil mist and strong shock of indoor use..

the apron, tee, the ball in front of the pneumatic float shall not be forcibly moving and swinging in order to avoid parts damage.

machine tool's electric parts, pneumatic components factory has been adjusted before the user shall not be adjusted freely, if there is any question, please contact the manufacturer.